Features:

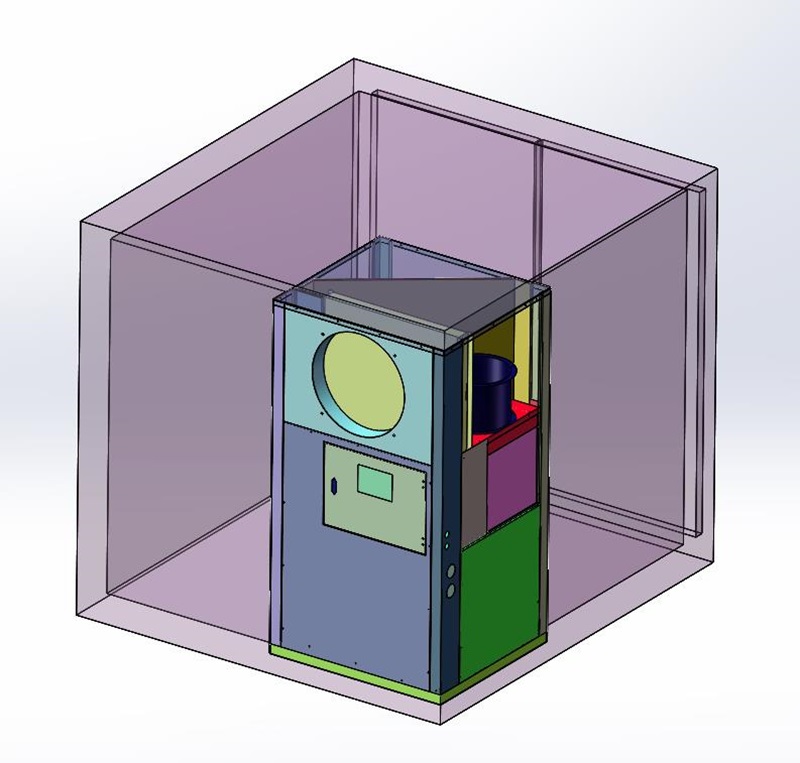

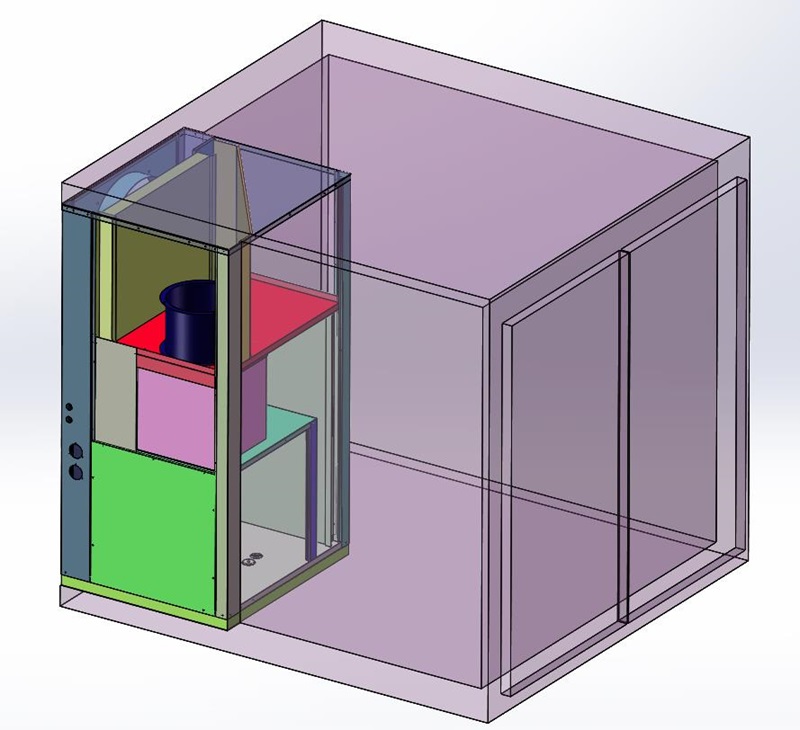

1. Preinstalled,no need assemble again, connecting power cables only.

2.Touch Screen Control

3. Remote control by WiFi(optional)

4. Stainless drying room body

5. High temperature and high humidity resistant hot air circulation fans

6. Stainless steel Fan Racks

7. Stainless steel trolley and trays

8. Electronic type humidity sensor

9. 10 sections, can set different temperature with different humidity and different drying time for different section.

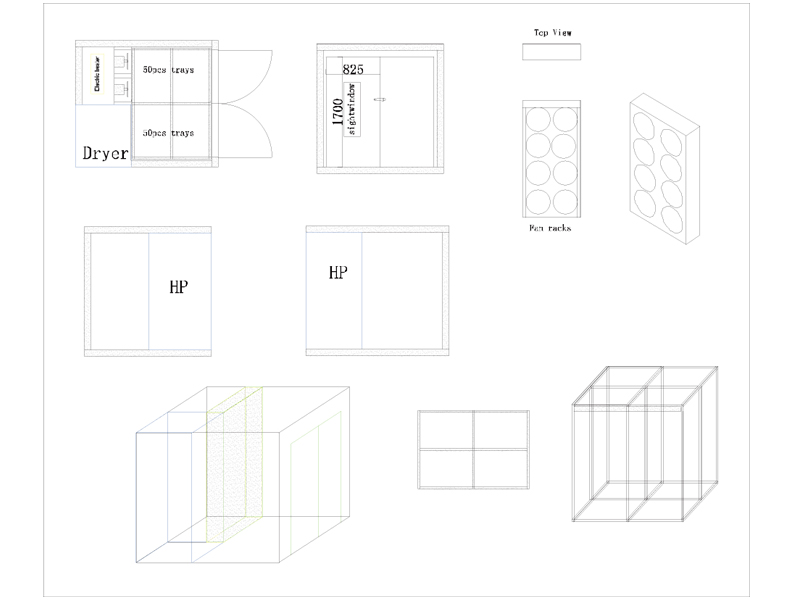

10. 100pcs trays, tray size 800*600*15 or 800*600*50mm

11. Each tray can loading 3-5Kg raw materials

Working Principle: Uses a heat pump system to recycle heat from the air, achieving low-temperature drying through a closed-loop process.

Advantages:

Energy-efficient: High thermal efficiency, consuming 50-70% less energy than traditional dryers.

Low-temperature protection: Suitable for heat-sensitive materials (e.g., fruits, herbs), preserving nutrients, color, and texture.

High efficiency and uniformity: Precise control of temperature and humidity ensures even drying.

Enclosed drying: Prevents contamination, meeting food hygiene standards.

Disadvantages:

High initial cost: Higher upfront investment compared to traditional dryers.

Longer drying time: Slightly slower than high-temperature equipment.

Applications: Fruits, vegetables, seafood, medicinal herbs, tea leaves, and other products requiring high-quality drying.

2. Hot Air Dryer

Working Principle: Uses electric heating or combustion to heat air, which removes moisture from the material’s surface.

Advantages:

Low cost: Low initial investment, ideal for small to medium businesses.

Fast drying speed: High-temperature airflow quickly removes moisture.

Easy operation: Simple technology, easy to maintain.

Disadvantages:

High energy consumption: Lower thermal efficiency leads to higher operating costs.

Impact on product quality: High temperatures can damage nutrients and appearance.

Pollution risk: May expose food to external air pollutants.

Applications: Nuts, grains, meat products, and items with lower quality requirements.

3. Freeze Dryer (Lyophilizer)

Working Principle: Freezes food, then removes moisture in a vacuum environment by sublimation.

Advantages:

Nutrient preservation: Minimizes nutrient loss while maintaining taste, shape, and color.

Extended shelf life: Extremely low moisture content prevents spoilage.

High added value: Ideal for premium food processing, such as medicinal herbs and specialty products.

Disadvantages:

High cost: Expensive equipment and operational costs.

Time-consuming: Longer drying cycles, not suitable for rapid large-scale production.

Applications: High-end food, medicinal herbs, coffee, instant fruit snacks, etc.

4. Microwave Dryer

Working Principle: Uses microwaves to heat water molecules inside food directly, quickly evaporating moisture for drying.

Advantages:

Fast drying: Direct heating ensures very high drying speed.

Good uniformity: Effective for drying complex-shaped materials.

Compact size: Requires less floor space, ideal for limited spaces.

Disadvantages:

Not suitable for large-scale production: Microwave penetration is limited.

Relatively high cost: Both equipment and operation are expensive.

Limited applicability: Some heat-sensitive foods may be affected.

Applications: Laboratory testing, small-batch high-value food processing.

5. Solar Dryer

Working Principle: Uses solar energy to heat air, with natural or forced ventilation to dry food.

Advantages:

Energy-efficient and eco-friendly: Uses renewable energy, no electricity needed.

Low cost: Simple equipment, suitable for small-scale setups.

Disadvantages:

Weather-dependent: Efficiency relies on sunlight, leading to inconsistencies.

Long drying time: Low efficiency limits output.

Poor hygiene: Susceptible to contamination from dust, insects, etc.

Applications: Small-scale drying of fruits and vegetables in rural or remote areas.

6. Vacuum Dryer

Working Principle: Reduces the boiling point of water under vacuum and removes moisture through low-temperature heating.

Advantages:

Low-temperature protection: Preserves nutrients, flavor, and quality of heat-sensitive foods.

High efficiency: Moisture evaporates quickly under vacuum.

Uniform drying: Produces even results with minimal deformation.

Disadvantages:

Expensive equipment: High initial and operational costs.

Limited capacity: Suitable for small-batch, high-value products.

Applications: Premium dried fruits and vegetables, medicinal herbs, chemical materials, etc.

Summary and Comparison

Type | Advantages | Disadvantages | Suitable Applications |

Heat Pump Dryer | Energy-efficient, low-temperature drying, uniform results | High initial cost, slower drying | High-quality fruits, herbs, seafood |

Hot Air Dryer | Low cost, easy to use, fast drying | High energy consumption, quality issues | Nuts, grains, meat products |

Freeze Dryer | Nutrient preservation, long shelf life, high value | Expensive, time-consuming | Premium food, medicinal herbs |

Microwave Dryer | Fast, uniform, compact | Limited capacity, high cost, some impact | High-value, small-batch products |

Solar Dryer | Eco-friendly, low cost | Weather-dependent, long drying time | Small-scale rural drying |

Vacuum Dryer | Low-temperature protection, uniform results | Expensive, limited capacity | Premium fruits, herbs, chemicals |

The choice of a food dryer depends on the properties of the food, production requirements, and budget constraints.

Heat Pump Dryer | |

Model | DT300B |

Power input | 5.5KW |

Electric heater | 9.0KW |

Power supply | 220V/1PH or 380-415V/3PH or 460-480V/3PH, 50/60HZ |

Rated current | 220V/1PH-66.0A 380-415V/3PH-29.0A 460-480V/3PH-29.0A |

Maximum current | 220V/1PH-80.0A 380-415V/3PH-35.0A 460-480V/3PH-35.0A |

Heating capacity | 10.5KW |

Cooling capacity | 7.8KW |

Level of protection | IPX4 |

Dehumidify capacity | 12.0L/H |

Suction Max. pressure | ≤0.75MPa |

Exhaust Max. pressure | ≤3.0MPa |

Noise | ≤75dB(A) |

Hot air flow | 12800-23600m³/H |

Protection Against electric shock | I |

Certification | CE |

Refrigerant | R134A 2.5KG |

Warranty | 1 Year |

Heat pump size | 960x860x1800mm |

Chamber size | L2200xW1950xW2100mm |

Whole Dimension | L2200xW1950xW2100mm |

Packing size | L2390xW2020xW2230mm |

Weight | 970KG |

Serial No. | / |

Production date | / |

Drytech(Guangzhou)Technology Co.,Ltd. | |

Copyright © 2025 drytechdryer All rights reserved. Sitemap Links: Drytech.com.cn Heat-Pump-Dryer.com Dryingmachine.net