1.Touch Screen Control

2. Remote control by WiFi(optional)

3. 100mm thickness Polyurethane panels, good heat insulation.

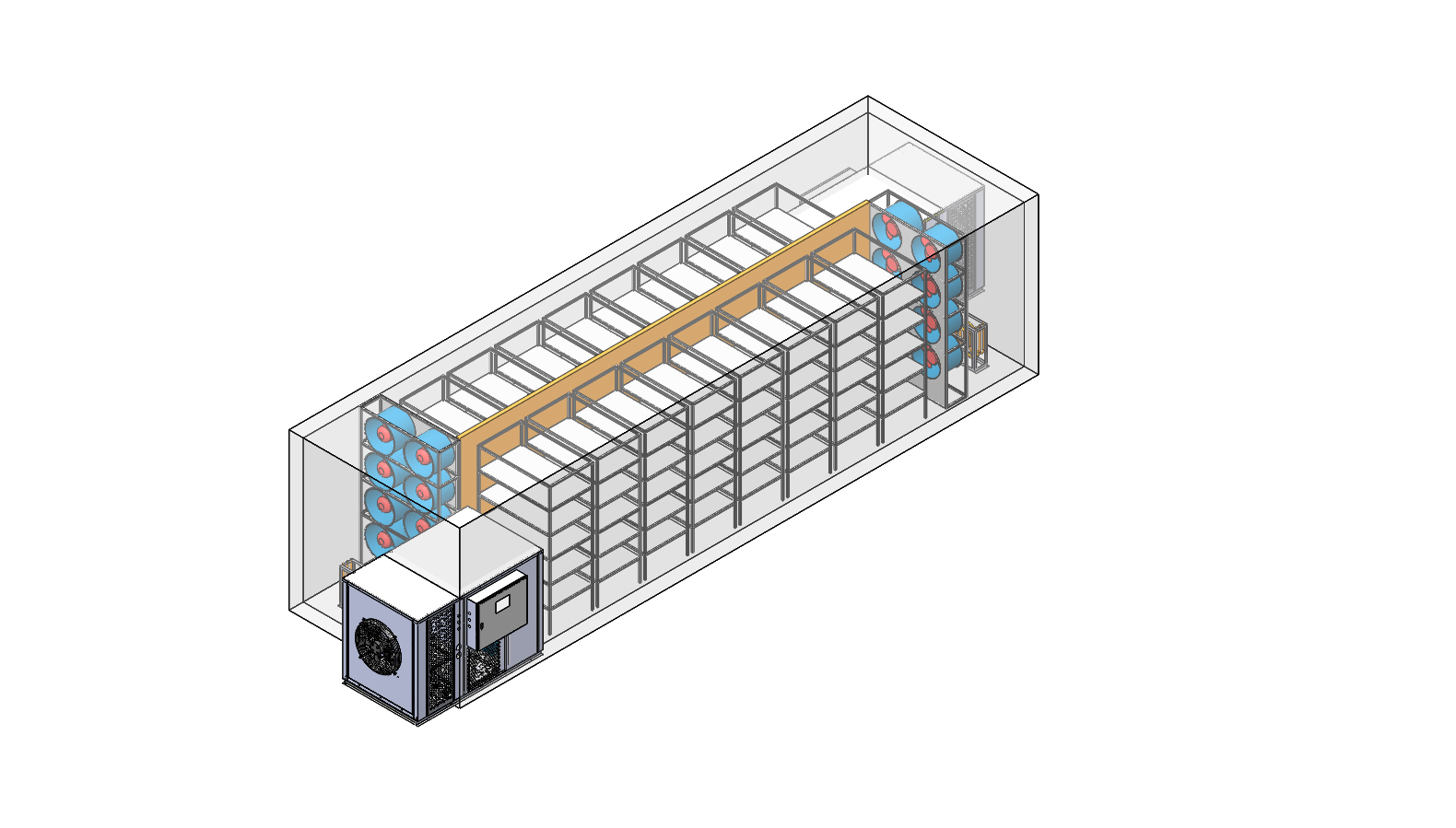

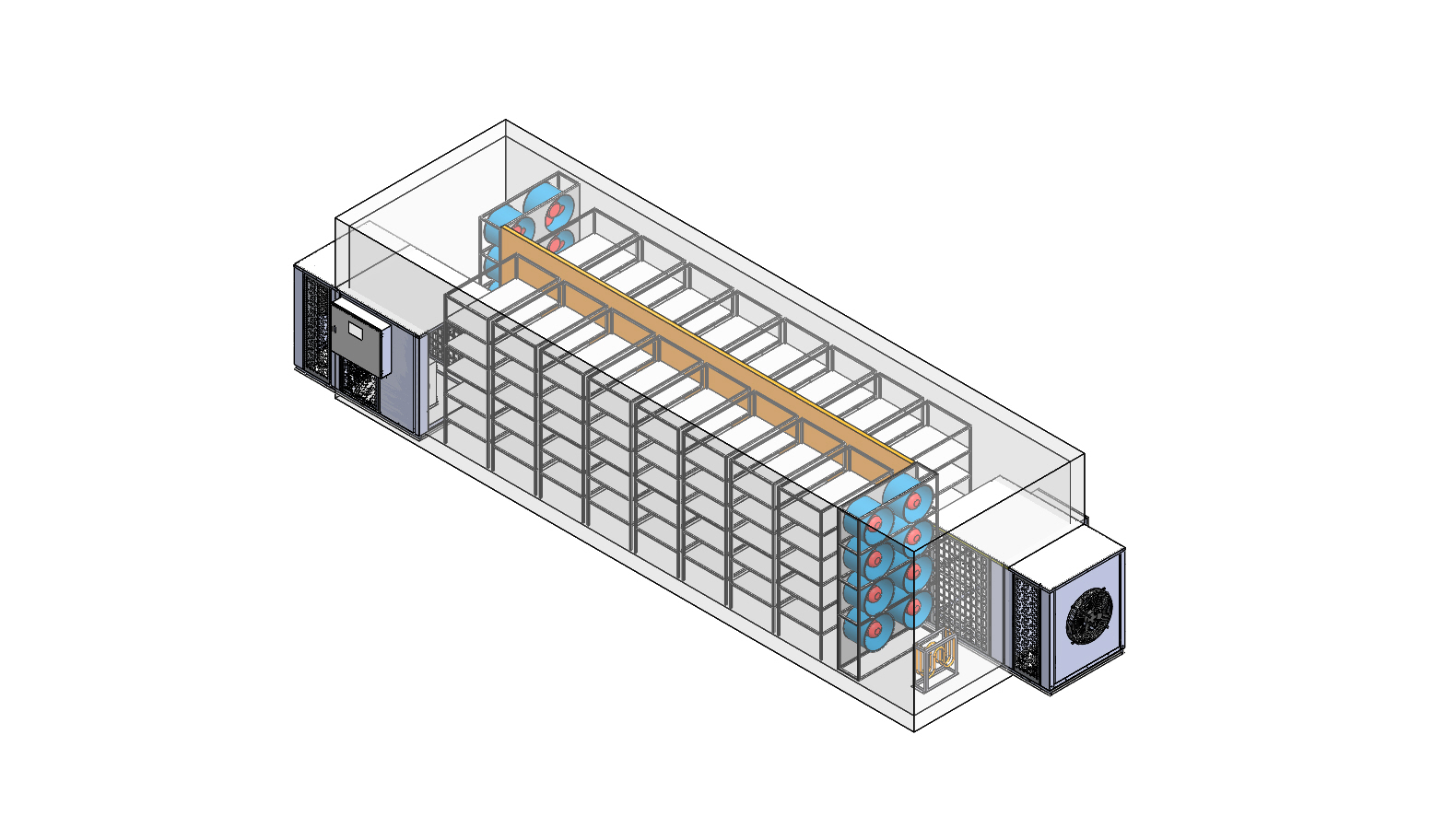

4. High temperature and high humidity resistant hot air circulation fans

4. Stainless steel Fan Racks

5. Stainless steel trolley and trays

6. Electronic type humidity sensor

7. 10 sections setting, can set different temperature with different humdity and different drying time for different section.

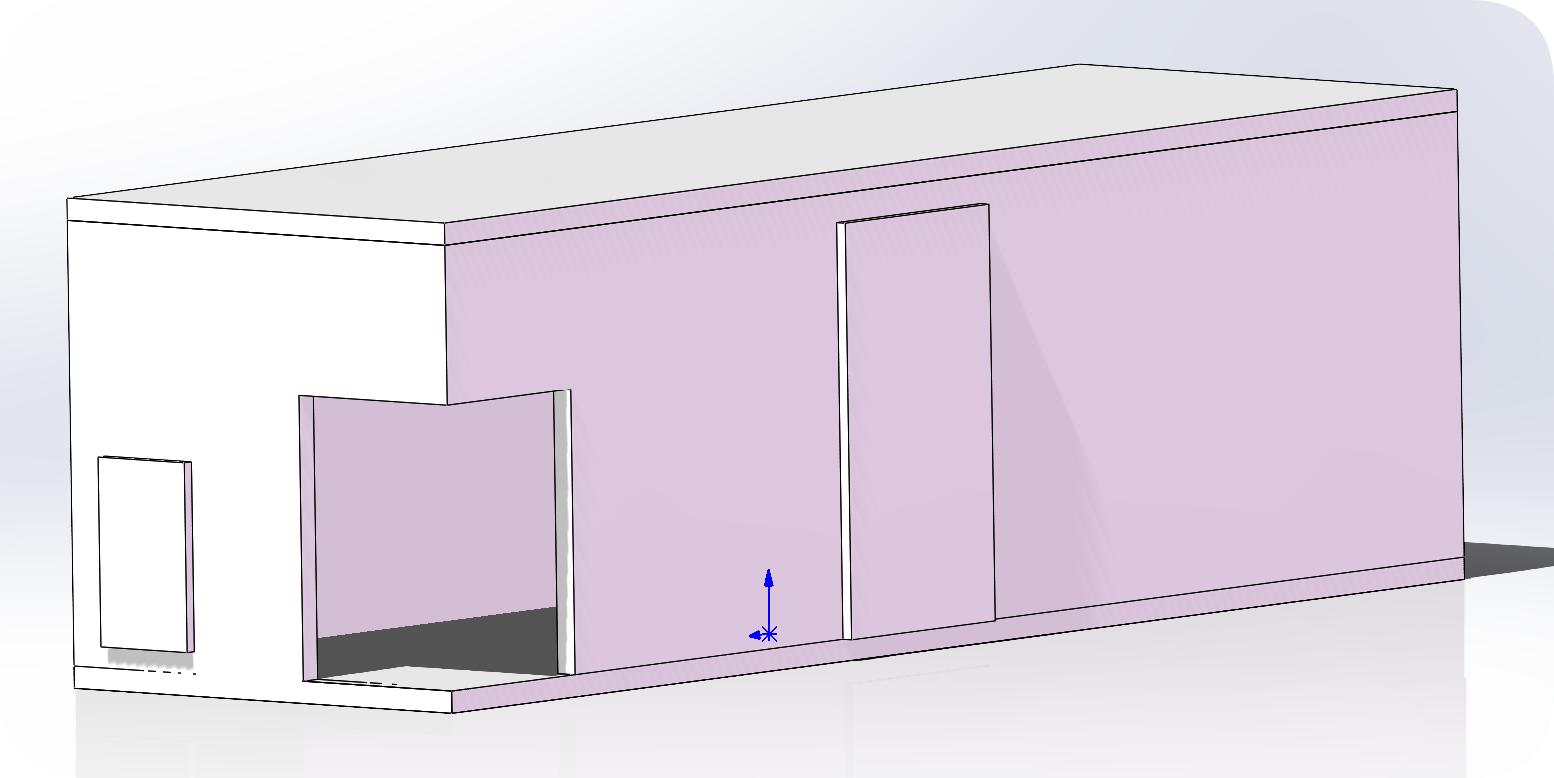

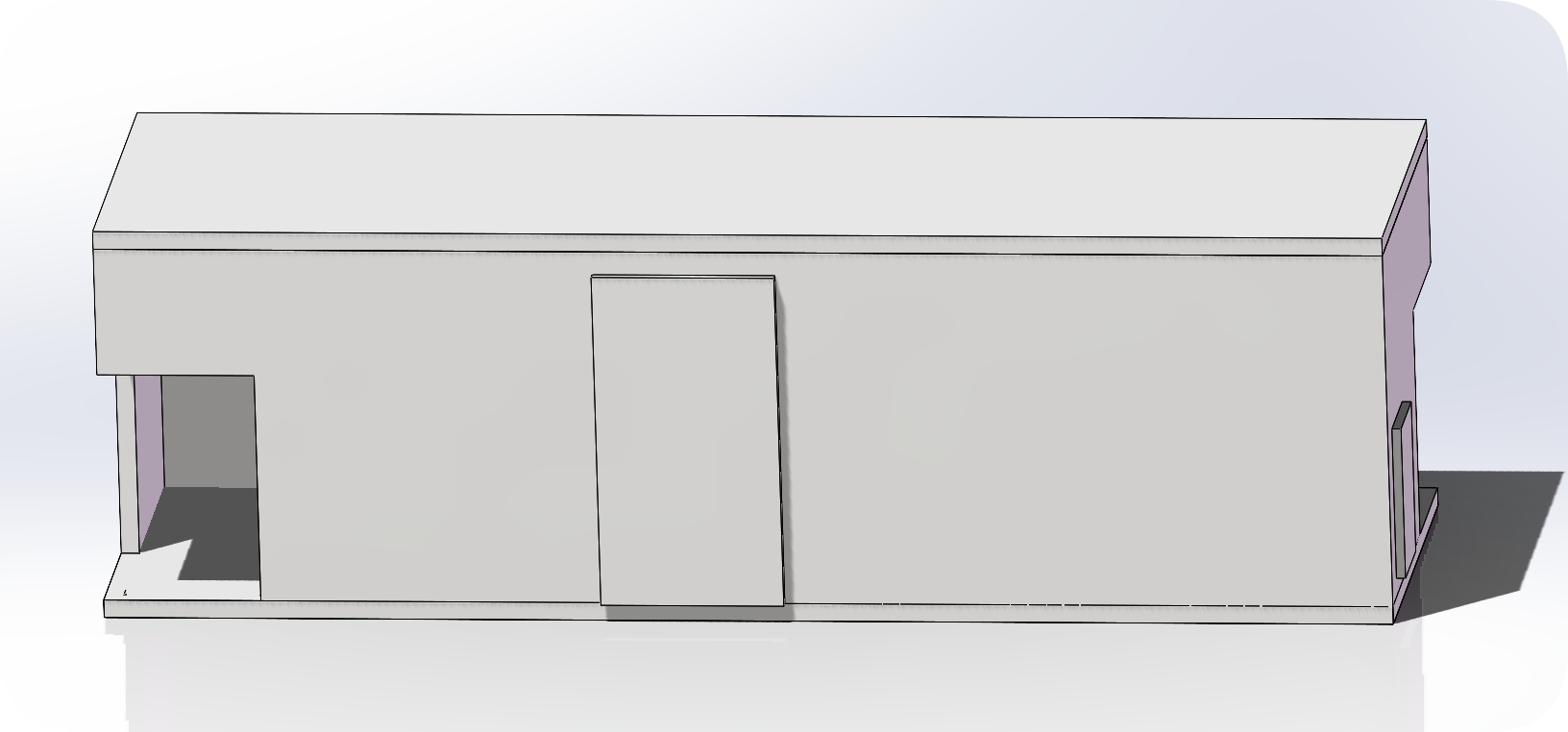

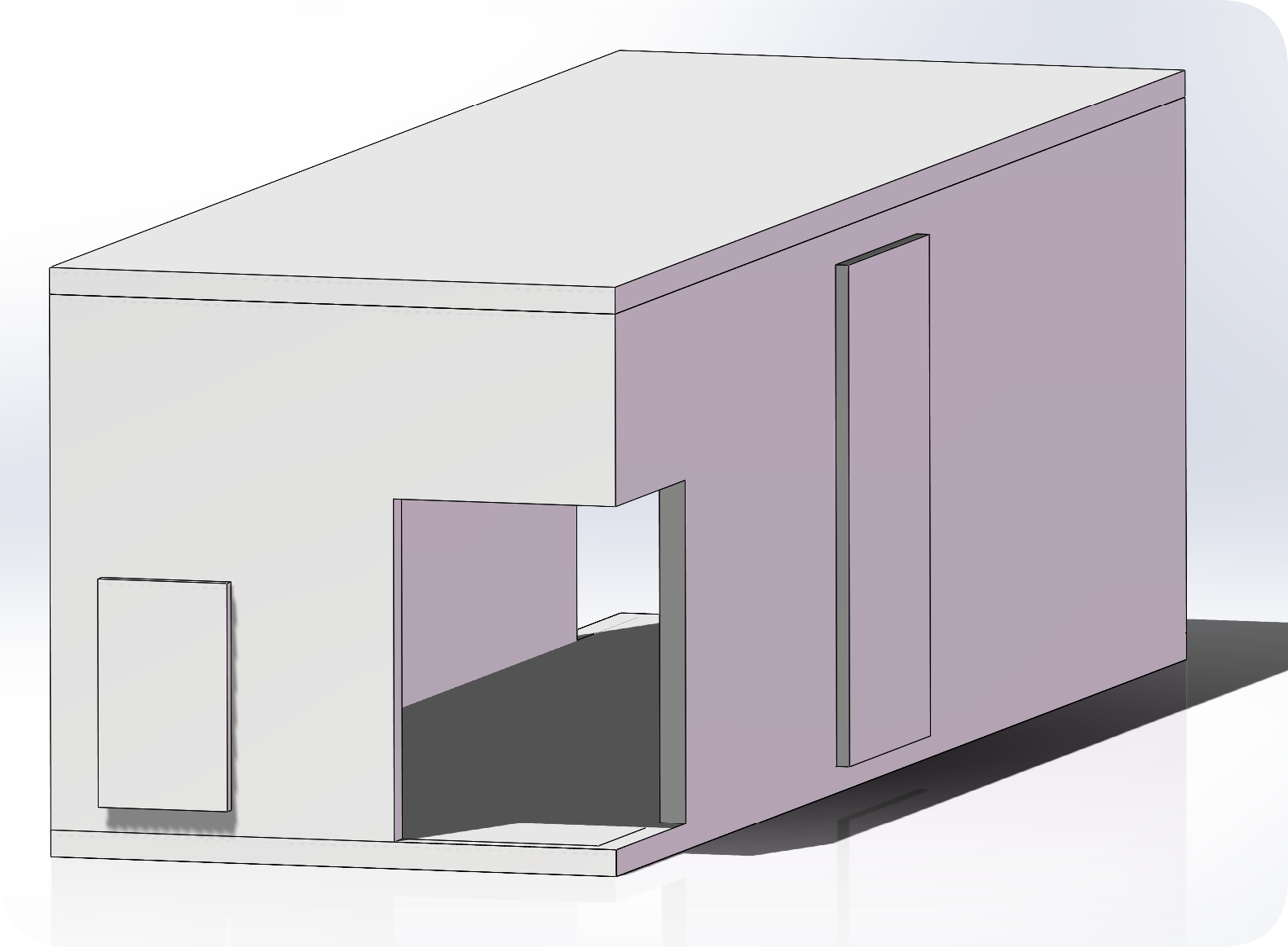

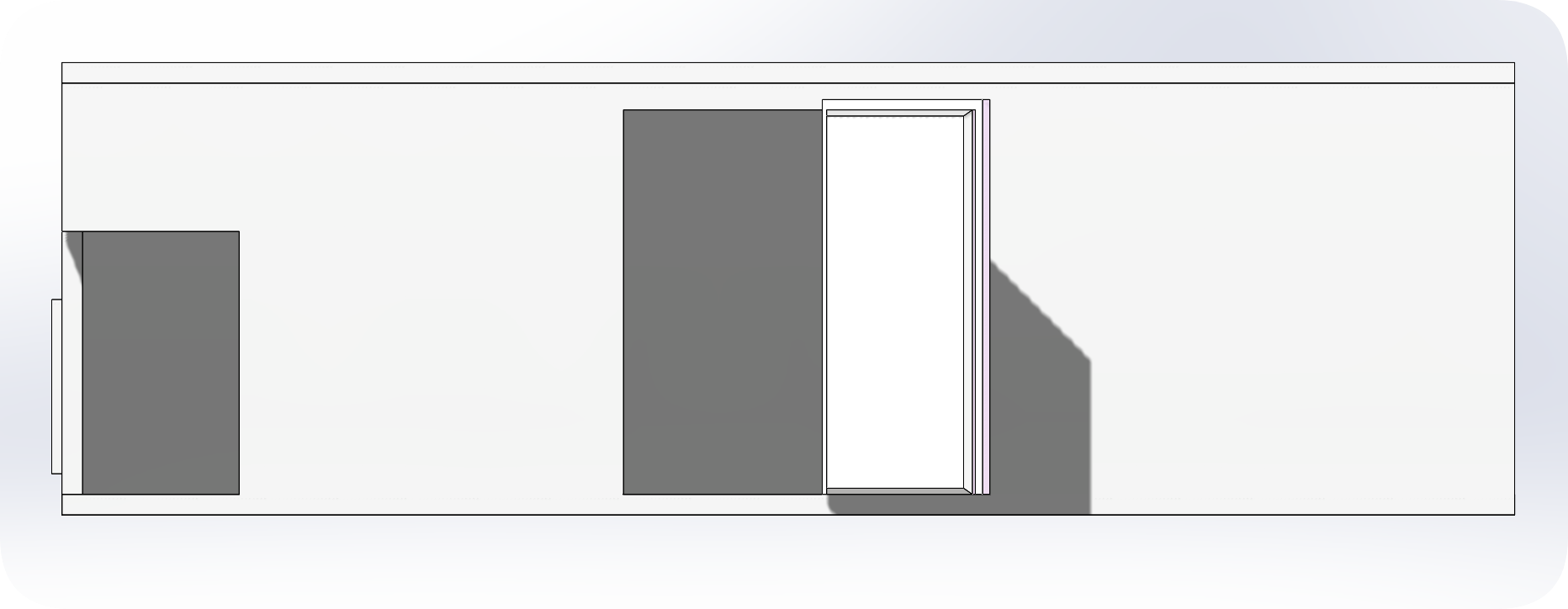

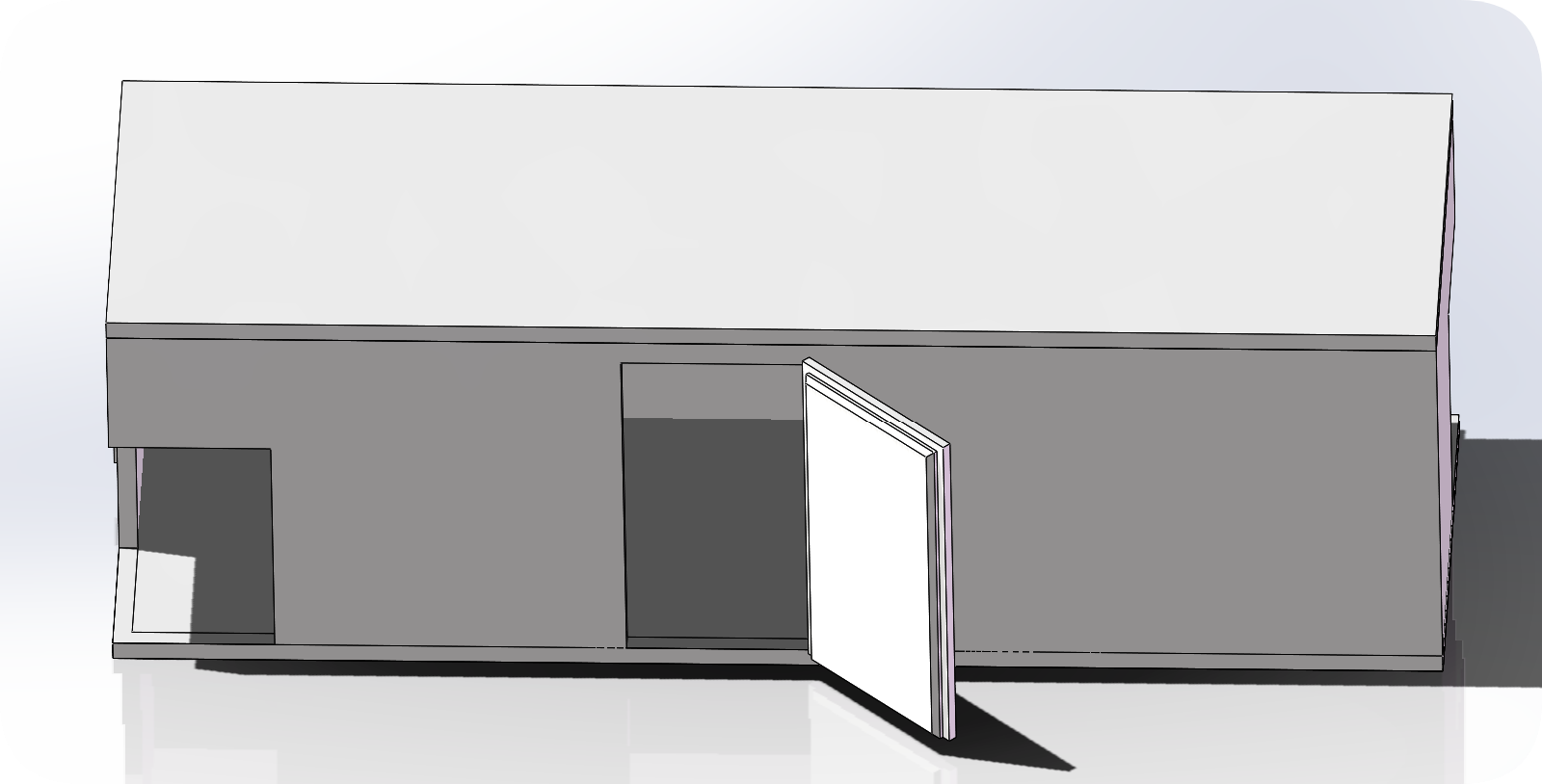

8. Detachable chamber design, saving transportation charges.

9. Easy assemble, packing with design drawing, and will send online installation videos.

Prospect Analysis of Heat Pump Dryer for Drying Fruits and Vegetables

Heat pump dryers have emerged as an innovative and sustainable technology for drying fruits and vegetables, addressing energy efficiency, product quality, and environmental concerns. Below is an analysis of their market prospects and potential growth drivers:

---

1. Market Trends

Growing Demand for Dried Fruits and Vegetables:

- Rising consumer preference for healthy, natural snacks and convenience foods drives demand for dried fruits and vegetables.

- Expanding use in industries like food processing, bakery, and ready-to-eat meals.

Global Shift Towards Sustainable Solutions:

- Heat pump dryers align with global sustainability goals by reducing energy consumption and minimizing environmental impact.

- Increasing regulations on energy efficiency and carbon emissions promote adoption.

---

2. Advantages of Heat Pump Dryers

-Energy Efficiency:

- Heat pump dryers use 50-70% less energy compared to conventional dryers, making them highly cost-effective in the long term.

Improved Product Quality

- Low-temperature drying preserves the natural color, flavor, nutrients, and texture of fruits and vegetables, meeting consumer demands for premium-quality products.

Adaptability and Versatility

- Suitable for various types of fruits (mangoes, apples, bananas) and vegetables (tomatoes, spinach, mushrooms).

- Can be used for seasonal and non-seasonal crops, supporting year-round operations.

Eco-Friendly Operation

- Uses a closed-loop system with minimal waste heat release, reducing its carbon footprint.

---

3. Growth Drivers

Expanding Agriculture and Food Processing Sectors:

- Rapid urbanization and population growth increase the demand for processed fruits and vegetables.

- Government incentives and subsidies for food processing industries encourage technology upgrades.

Technological Advancements:

- Enhanced automation, IoT integration, and better controls improve dryer performance and usability.

-Rising Awareness of Food Waste:

- Drying surplus produce extends shelf life, addressing food wastage challenges.

Export Potential:

- Dried fruits and vegetables have strong export demand, especially in regions with limited agricultural seasons (e.g., Europe, North America).

---

4. Challenges

- High Initial Investment:

- Capital costs are higher compared to traditional dryers, which may deter smaller businesses.

- Competition from Traditional Drying Methods:

- Hot air and solar dryers dominate in low-cost markets, offering cheaper alternatives despite lower efficiency and quality.

- Awareness and Adoption Barriers:

- Limited knowledge among small-scale producers about the benefits of heat pump dryers can slow adoption.

---

5. Regional Opportunities

- Asia-Pacific:

- Largest producer and consumer of fruits and vegetables, with rising adoption of advanced drying technologies in countries like China and India.

- Government support for energy-efficient technologies provides significant growth opportunities.

- **Europe and North America:

- High demand for premium dried products and stringent energy efficiency standards drive market growth.

- Consumers’ focus on organic and minimally processed foods boosts heat pump dryer adoption.

Africa and Latin America:

- Rich agricultural resources and growing export opportunities create demand for efficient drying technologies.

---

6. Future Outlook

R&D Focus:

- Research into hybrid drying systems (e.g., combining heat pump with solar) can enhance cost-effectiveness and applicability in developing regions.

- Advances in control systems and AI integration will optimize drying cycles and energy usage.

Market Growth:

- The global market for heat pump dryers is expected to grow steadily, with significant expansion in the food processing industry.

Potential Applications Beyond Fruits and Vegetables:

- As technology improves, heat pump dryers may find applications in drying other products like seafood, herbs, and spices.

---

Conclusion

The heat pump dryer holds strong growth potential in the drying of fruits and vegetables due to its energy efficiency, superior product quality, and alignment with global sustainability trends. While challenges like high initial costs exist, increasing demand for dried products, government incentives, and technological advancements provide a favorable market outlook. Businesses adopting this technology can gain a competitive edge in the high-quality and eco-friendly food segment.

The heat pump dryer has significant economic value and environmental protection effect in the process of drying apple slices, which is specifically reflected in the following aspects:

Economic value:

Energy saving and consumption reduction:

The heat pump dryer uses electric energy to drive the compressor to transfer heat from the environment to the drying chamber. It has a high energy efficiency ratio and can reduce energy consumption by 40%-60% compared to traditional fuel, gas or coal-fired drying equipment.

The operating cost is low and long-term use can save a lot of energy costs.

Improve product quality:

The heat pump dryer can accurately control the drying temperature and humidity to ensure that the apple slices are dried under optimal conditions, maintaining the color, taste and nutritional content, and improving product quality.

Uniform drying effect reduces product loss and improves yield.

High degree of automation:

The heat pump dryer is simple to operate, can realize automated control, reduce manual intervention, and reduce labor costs.

The equipment operates stably and has low maintenance costs, reducing downtime and repair costs.

Extend equipment life:

The heat pump system runs smoothly, has no combustion process, has little equipment wear and long service life, and reduces equipment replacement and maintenance costs.

Improve production efficiency:

The heat pump dryer can work continuously and has a short drying cycle, which improves production efficiency and increases production capacity.

Environmental protection effect:

Reduce pollutant emissions:

The heat pump dryer is driven by electricity, has no combustion process, does not produce waste gas, waste water, waste residue and other pollutants, and meets environmental protection requirements.

Helps reduce greenhouse gas emissions and lowers carbon footprint.

Comply with environmental protection policy:

As environmental protection policies become increasingly strict, traditional high-pollution drying equipment may face elimination. The use of heat pump dryers complies with national environmental protection policies and avoids future environmental risks.

Improve the working environment:

The heat pump dryer operates quietly, without smoke and odor, improving the working environment and worker satisfaction.

Resource recycling:

Some heat pump dryers can recycle the condensed water generated during the drying process to achieve recycling of water resources.

In summary, the heat pump dryer can not only bring significant economic benefits during the drying process of apple slices, but also effectively reduce environmental pollution and meet the requirements of sustainable development. With the continuous advancement of technology and the improvement of environmental protection requirements, heat pump dryers will have broader application prospects in the future.

Project Time: 2020

Project Location: Turkey

Drying Material: Apple Slices

Daily Drying Capacity: 2.4 tons

This project utilizes three sets of Drytech brand heat pump dryers, model DT300HD. Each heat pump dryer has an input power of 11 KW. Each dryer chamber can accommodate 16 trolleys, with each trolley holding 16 trays. The tray dimensions are 800*600*50 mm, and each tray can hold 3.2 kg of fresh apple slices. The total material capacity is calculated as 16*16*3.2*3 = 2458 kg.

Drying Time: 10 hours

Drying Process:

The process is divided into two phases:

1. First Phase:

o Temperature: 65°C

o Humidity: 25%

o Duration: 2 hours

o Mode: HDry

2. Second Phase:

o Temperature: 65°C

o Humidity: 10%

o Duration: 8 hours

o Mode: HDry + Moisture

This project demonstrates the efficient use of heat pump dryers

for large-scale apple slice drying, ensuring high-quality output

with controlled temperature and humidity settings.

Heat Pump Dryer | |

Model | DT300HD |

Power input | 11.0KW |

Electric heater | 18.0KW |

Power supply | 220V/1PH or 380-415V/3PH or 460-480V/3PH, 50/60HZ |

Rated current | 220V/1PH-132.0A 380-415V/3PH-58.0A 460-480V/3PH-58.0A |

Maximum current | 220V/1PH-160.0A 380-415V/3PH-70.0A 460-480V/3PH-70.0A |

Heating capacity | 21.0KW |

Cooling capacity | 15.6KW |

Level of protection | IPX4 |

Dehumidify capacity | 24.0L/H |

Suction Max. pressure | ≤0.75MPa |

Exhaust Max. pressure | ≤3.0MPa |

Noise | ≤75dB(A) |

Hot air flow | 25600-47200m³/H |

Protection Against electric shock | I |

Certification | CE |

Refrigerant | R134A 2.5KG |

Warranty | 1 Year |

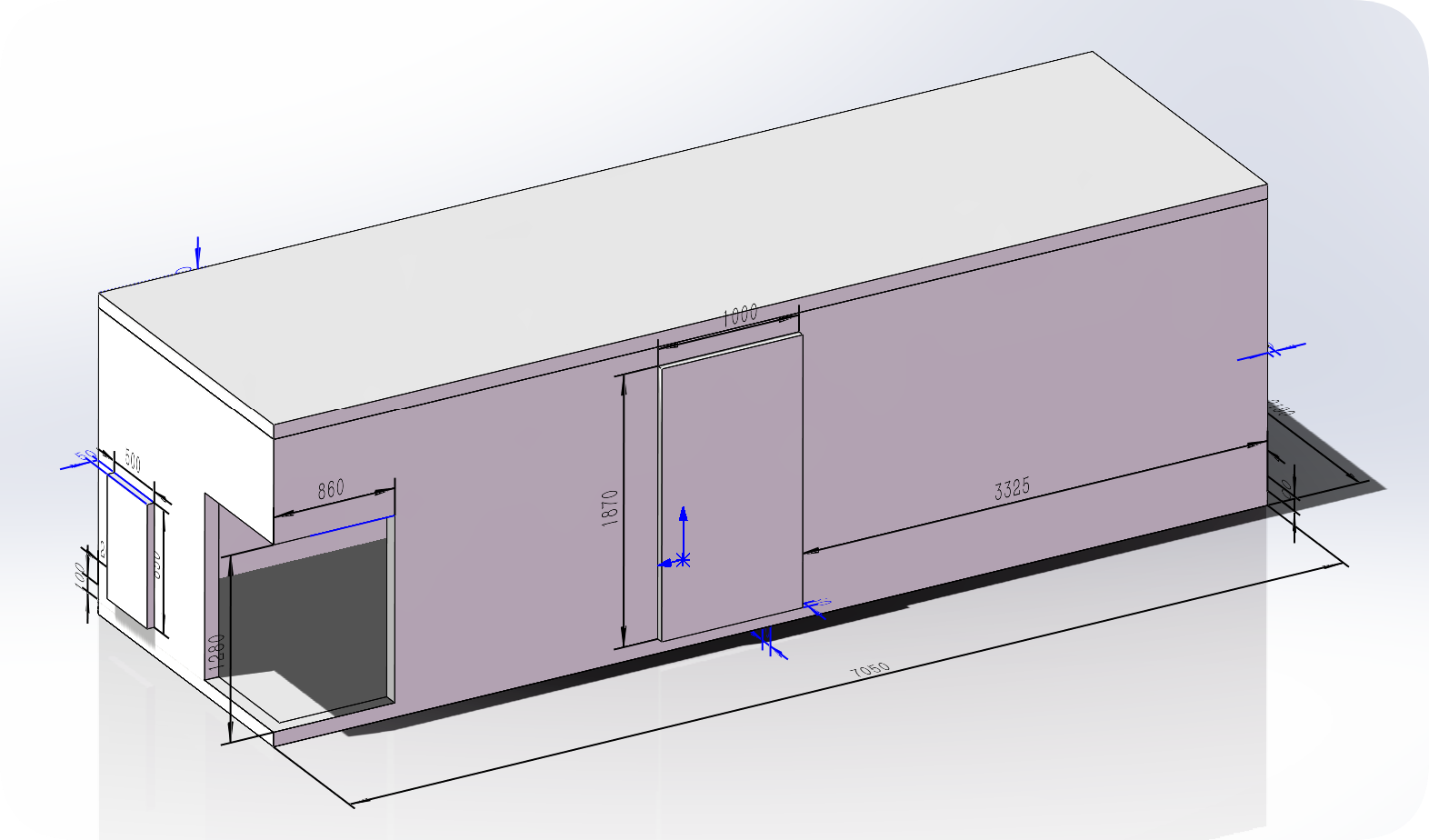

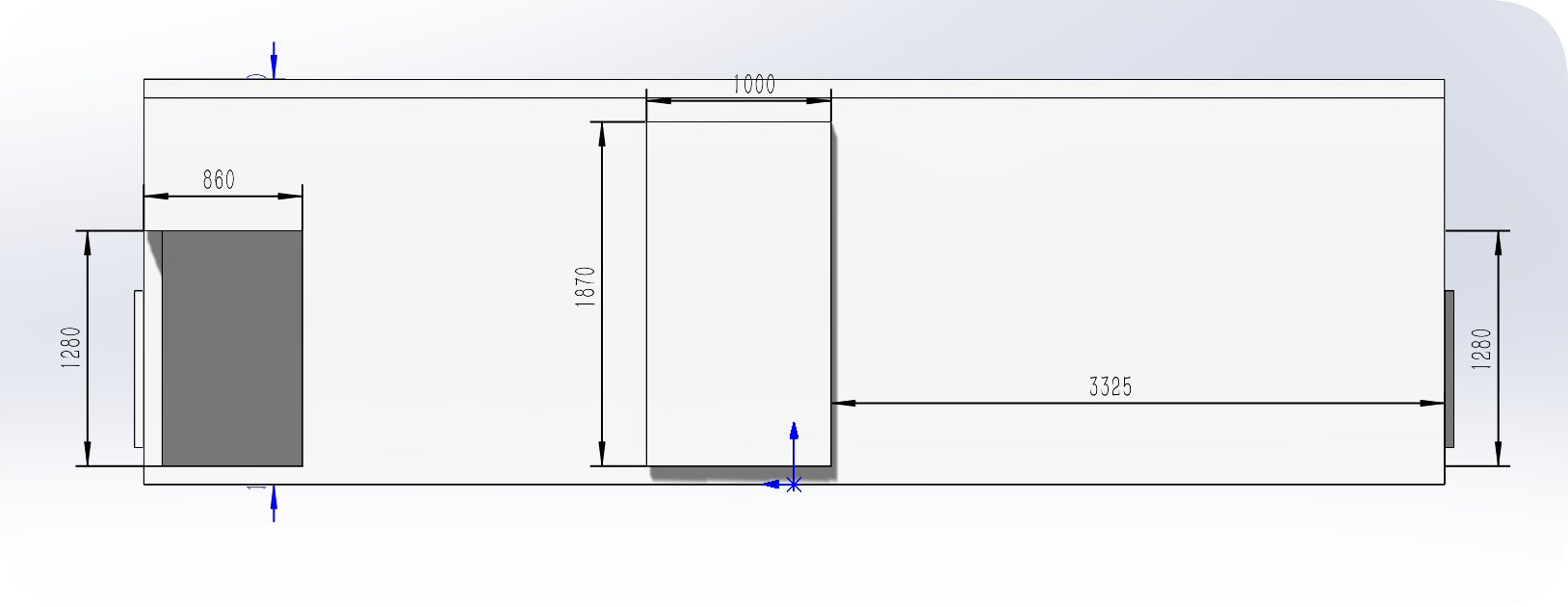

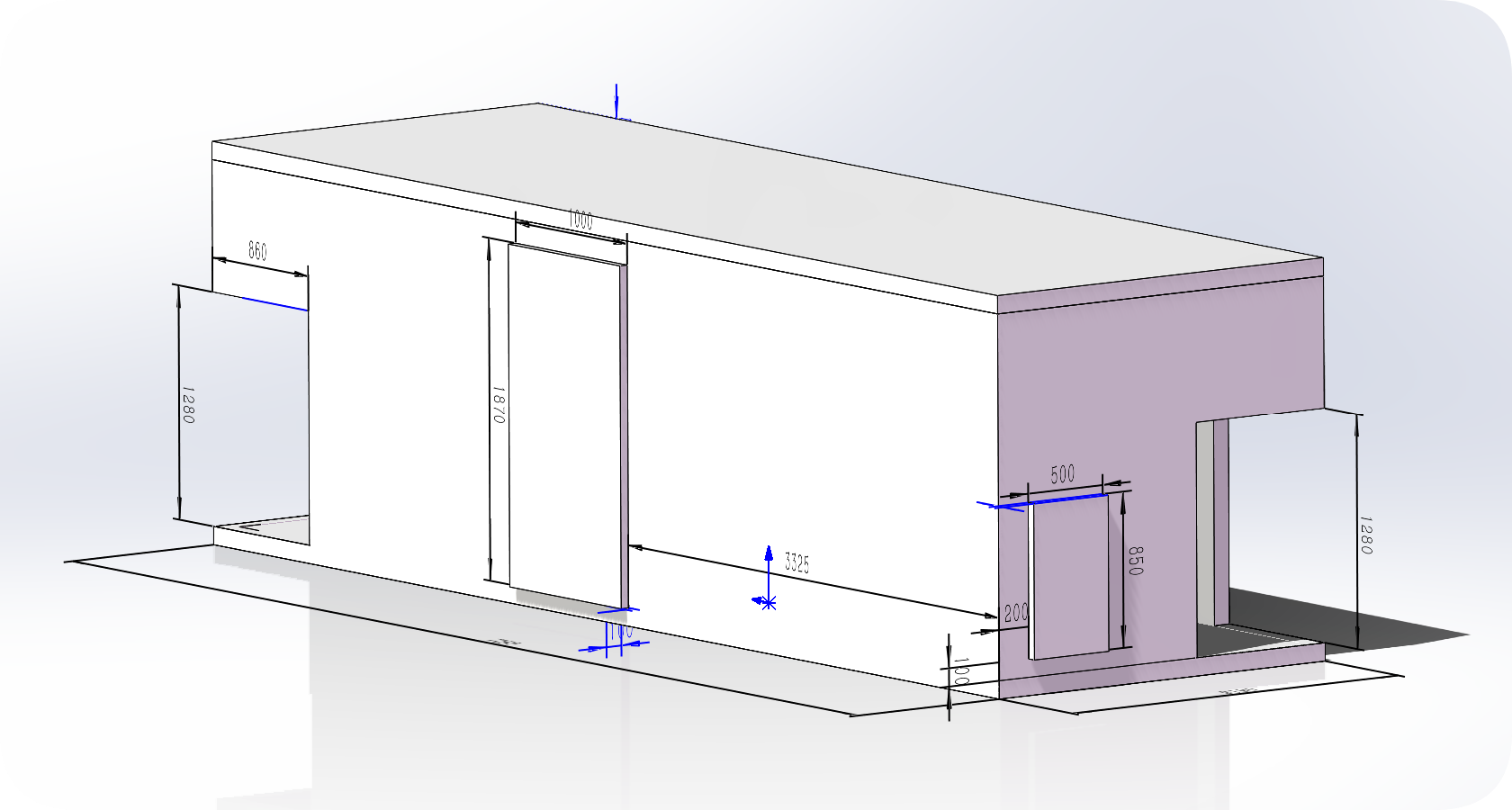

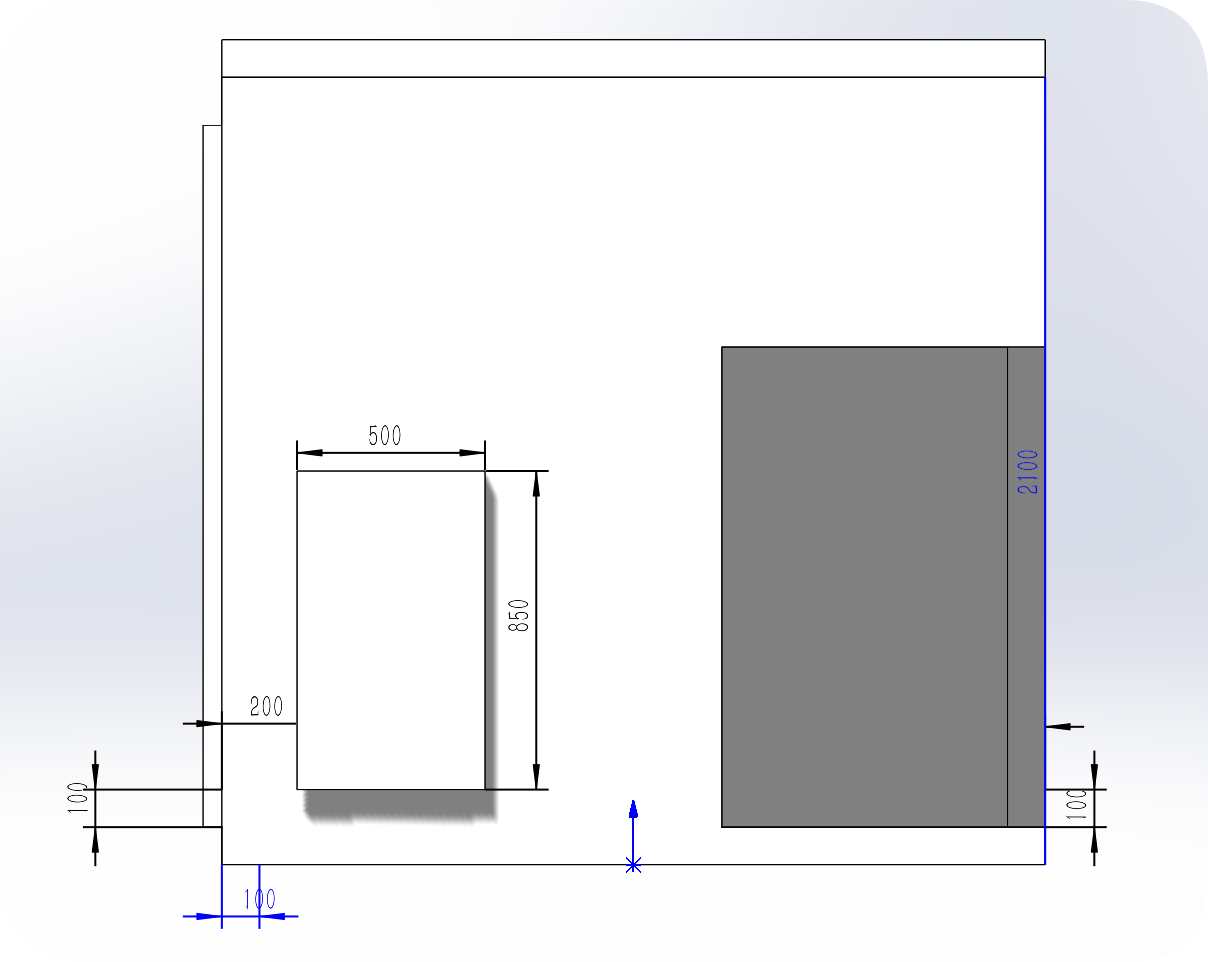

Heat pump size | 1650x860x860mm |

Chamber size | L7050xW2190xW2200mm |

Whole Dimension | L9000xW2190xW2200mm |

Delivery by FCL | 20Ft container |

Weight | 3000KG |

Serial No. | / |

Production date | / |

Drytech(Guangzhou)Technology Co.,Ltd. | |

Drytech heat pump dryers marketing FAQ

---------------------------------------------------------

1. What are the unique features and benefits of Drytech heat pump dryers?

Drytech heat pump dryers(food drying machine/fruitdrying machine/petfood drying machine/fish drying machine) have several uniquefeatures and benefits, including energy efficiency, reduced environmentalimpact, and superior drying results. They use advanced heat pump technology torecycle hot air and minimize energy consumption, resulting in lower electricitybills and reduced carbon emissions. Additionally, Drytech heat pump dryers aregentler on products than traditional dryers, reducing wear and tear on clothingand extending their lifespan, also lower temperature drying food like sun dry, Lowtemperature drying, no loss of nutrients, no damage to the physical structureof the product, discoloration.

2. Who are the target customers for Drytech heat pump dryers?

The target customers for Drytech heat pump dryersare environmentally conscious individuals or companies who are looking for anenergy-efficient and sustainable alternative to traditional dryers. They mayalso be interested in the superior drying results that Drytech heat pump dryerscan provide, Application field including food drying companies, petfoodcompanies, dried fruit companies, dried fish companies etc.

3. What are the pain points and needsof the target customers that can be addressed by Drytech heat pump dryers?

The pain points and needs of the target customersthat can be addressed by Drytech heat pump dryers include high energy costs,concern for the environment, and a desire for gentle and effective drying of products.

4. How does Drytech heat pump dryerscompare to other types of dryers in terms of efficiency and effectiveness?

Compared to other types of traditional dryerssuch as electric dryers, gas dryers, coal dryers,Drytech heat pump dryers aresignificantly more energy-efficient, with energy savings of up to 75% comparedto traditional dryers. They also provide superior drying results, with fasterdrying times and gentler treatment of products.

5. What are the environmentalbenefits of using Drytech heat pump dryers?

The environmental benefits of using Drytech heatpump dryers include reduced carbon emissions and lower energy consumption.Drytech heat pump dryers use advanced heat pump technology to recycle hot air,resulting in significantly lower energy consumption and reduced carbonemissions compared to traditional dryers.

6. What are the pricing options forDrytech heat pump dryers?

The pricing options for Drytech heat pump dryerswill depend on various factors, such as the model and features of the dryer, aswell as the retailer or distributor selling the dryer. Generally, Drytech heatpump dryers are priced at a premium compared to traditional dryers due to theirenergy efficiency and superior drying results.

7. What is the distribution strategyfor Drytech heat pump dryers?

The distribution strategy for Drytech heat pumpdryers will depend on the target market and the availability of distributionchannels. Drytech heat pump dryers can be sold through online retailers,specialty stores, and home appliance retailers. Additionally, Drytech mayconsider partnering with distributors and wholesalers to expand their reach andavailability.

8. What are the potentialdistribution channels for Drytech heat pump dryers?

The potential distribution channels for Drytechheat pump dryers include online retailers, specialty stores, home applianceretailers, and wholesalers. Drytech may also consider partnering with othercompanies to expand their reach and availability.

9. How can Drytech heat pump dryersbe promoted to potential customers?

Drytech heat pump dryers can be promoted to potentialcustomers through various marketing channels, such as social media, onlineadvertising, content marketing, email marketing, and influencer marketing. Theycan also be promoted through traditional advertising methods, such as TV,radio, and print ads.

10. What are the key messages thatshould be communicated in Drytech heat pump dryers' marketing?

The key messages that should be communicated inDrytech heat pump dryers' marketing include their energy efficiency,environmental sustainability, superior drying results, and gentleness onfabrics. The marketing should also highlight the cost savings and reducedcarbon footprint that come with using Drytech heat pump dryers.

11. What are the potential barriers toadoption for Drytech heat pump dryers?

Potential barriers to adoption for Drytech heatpump dryers may include their higher price point compared to traditionaldryers, a lack of awareness or education about the benefits of heat pumptechnology, and resistance to change from traditional drying methods.

12. What are the potentialcollaborations that Drytech could pursue to increase brand awareness?

Drytech could collaborate with influencers in thesustainability and home appliance industries to increase brand awareness.Additionally, they could partner with environmental organizations to promotethe environmental benefits of using Drytech heat pump dryers.

13. What are the potential customerloyalty programs that Drytech could implement?

Drytech could implement customer loyalty programsthat reward customers for repeat purchases, referrals, and social mediaengagement. Additionally, they could offer extended warranties or maintenanceplans to incentivize customers to choose Drytech heat pump dryers overtraditional dryers.

14. What are the potentialopportunities for Drytech in international markets?

There is potential for Drytech to expand intointernational markets, particularly in regions with high energy costs or astrong focus on sustainability. Drytech could partner with distributors orwholesalers in these regions to expand their reach and availability.

15. How can Drytech differentiateitself from competitors in the heat pump dryer market?

Drytech candifferentiate itself from competitors in the heat pump dryer market byhighlighting the superior drying results, energy efficiency, and gentleness on productsthat Drytech heat pump dryers offer. They could also differentiate themselvesby offering exceptional customer service, such as extended warranties ormaintenance plans, and by positioning themselves as a sustainability-focusedcompany.

16. What are the potential influencermarketing strategies that Drytech could implement?

Drytech could partner with influencers in thesustainability and home appliance industries to promote the benefits of usingDrytech heat pump dryers. These influencers could share their personalexperiences with the product or create sponsored content highlighting theenergy savings and environmental benefits.

Copyright © 2025 drytechdryer All rights reserved. Sitemap Links: Drytech.com.cn Heat-Pump-Dryer.com Dryingmachine.net